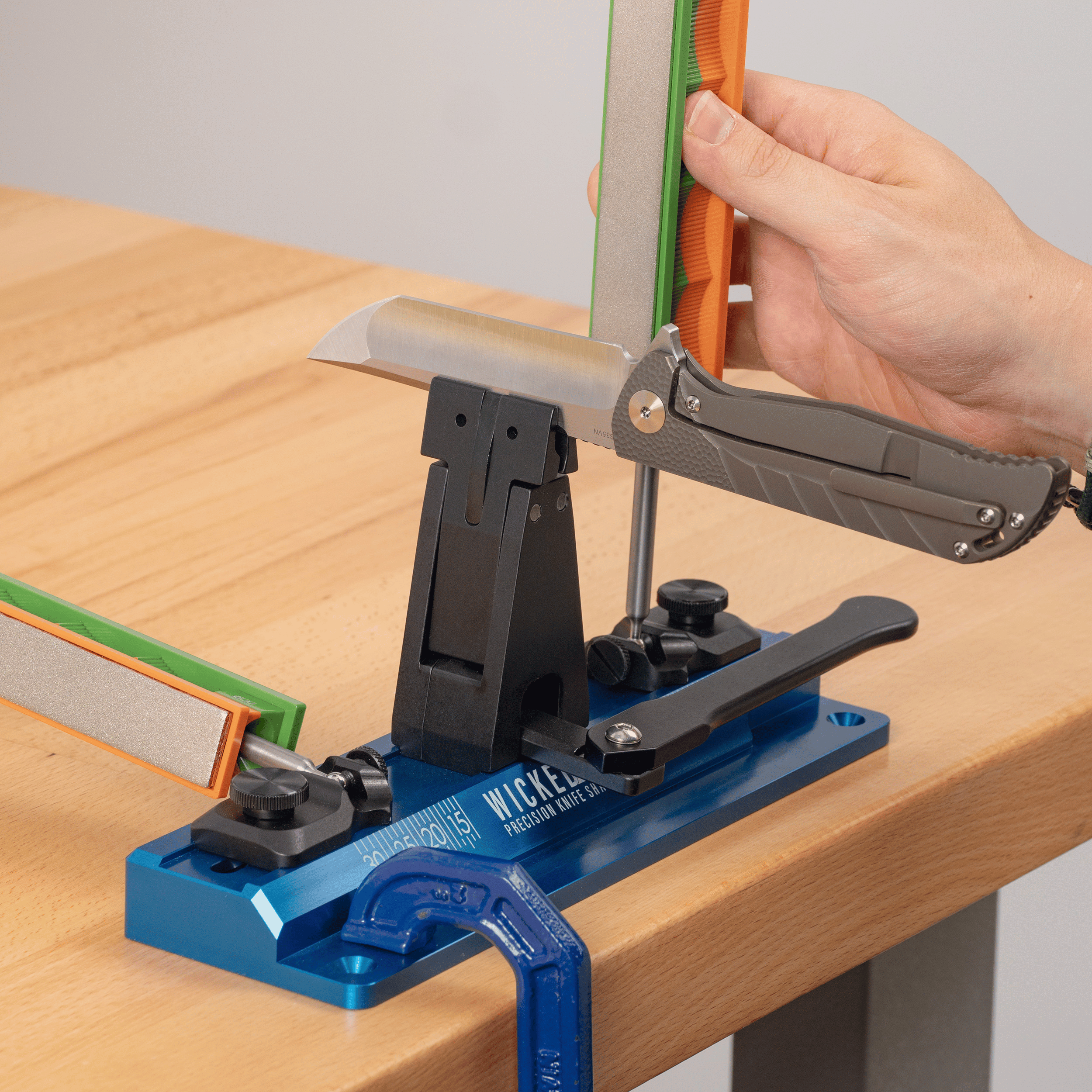

Finally got a couple of hours to try out my WE64 Pro Kit. I had watched tge instruction videos several times and having them at hand as I set the WE64 up was amazingly useful.

I was a bit impatient so I did not use the trainer blade. My EDC is a Benchmade Barrage (S30V steel, spear point blade profile). I’ve had it around 5 years or so, so the factory edge is long gone. I’ve made some attempts to sharpen with limited success. It also had some ‘dings’ in the edge that my best effort's to date had liitle effect on.

So, I went through the ‘training’ steps using the Barrage. One caveat, it is near impossible to use the precision depth tool with my Barrage. There is no flat surface in the blade profile - it tapers from a midline ridge to both the edge and the spine. If it is not set at full depth, the taper to the spine would squeeze the blade out of the holder as it was closed. My Barrage does have the black DLC finish, so it is probably slicker than a plain steel finish.

I started with the 200 grit stones gound the approximate angle at 22dg, then started with the 200 grit stones gound to both establish the burr and work out the dings in the edge. I found I don’t have a reliable ferl for the burr, but dragging the edge of a business card gave a relatively positive burr indicator.

I took most of my time with the 200 grit stones to establish a consistent edge angle profile - an issue I had induced over the years.

Once that was done, it was a very intuitive process to step from [****]. I stopped at 800 grit since I didn’t need any finer for an EDC. The change in tone as each successive grit worked out the prior grits finish was distinctive, so easy to gauge progress.

I believe my Benchmade Barrage is sharper now than it was new, and it WE64 made it easy - for values of easy.

It takes a little while before the stone stroke motion becomes ‘natural’, but slow, smooth seems to work best.

Best investment for my knives I could have made!